Translume offers both Microfluidic Chips and Flow Cells on a standard and custom-design basis. These two product families have microfluidic channels with different optical characteristics, which may affect your application.

Microfluidic Chips have microfluidic channels that are optically clear on either the top or the bottom. The opposite side is translucent (see below for our definition of translucent), and so are the channel sidewalls. In contrast, Flow Cells have channels that are optically clear on both the top and the bottom (the sidewalls are translucent).

Transparent and Translucent Surfaces

We are all familiar with the term “transparent”. Light passes through a transparent surface without being absorbed and without being scattered, and objects can be viewed clearly through transparent surfaces.

The term “translucent” is not as common. Light passes through a translucent surface without being absorbed, but a translucent surface will introduce some scattering. Some of the photons that reach a translucent surface will be unaffected, continuing onto their original path. Others will be scattered toward new paths. The amount of light that is scattered and the direction of the scattering is a function of the surface morphology (i.e. function of its texturing). The scattering may be mild, in which case an image can be viewed through a translucent surface with only some minor degradation; or the scattering can be severe, in which case one cannot see an object clearly, but rather one only perceives light and dark area.

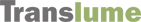

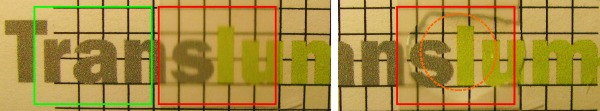

The photographs below illustrate the difference between transparent and translucent. We show an object (text and grid) seen through:

- A polished glass surface (this is our reference)

- A glass surface machined by Translume. This surface morphology is similar to that of a microfluidic channel floor.

- The same machined surface, but this time with some water added on top of it.

The reference surface has an optical finish: the object seen through this glass surface (green rectangle) is clearly visible and the image details readily apparent. In contrast, the image seen through the machined surface (red rectangle) shows some obvious degradation. The text is readable, but the edges of the letters are no longer sharply defined; the scattering is sufficiently weak that the image is still quite luminous.

The right photograph shows the identical text and grid seen through the same machined surface. But this time, the machined surface has been covered with water (orange circle), which minimizes the scattering effect. The image degradation is much less severe than in the test without the water; in fact, the image degradation is almost imperceptible. The image improvement is due to better matching of the index of refraction of the water and the glass compared to that of the air and the glass; this reduces the effective scattering. This case corresponds closely to what you might expect when using one of our microfluidic chips.

and one more example